Shipham-valves

Shipham-valves

| Adress: |

Hawthorn Avenue

HU3 5JX Hull East Yorkshire, United Kingdom |

| Telephone: | +44 (0) 1482 323163 |

| E-mail: | sales@shipham-valv... |

| Website: | www.shipham-valves... |

Product description

Shiphams have vast experience of supplying and manufacturing Gate Valves, to a wide range of industries and applications. Our gate valve range is renowned worldwide for been a quality product you can rely on. We manufacture our gates from a wide range specialist material and our engineers are on hand to ensure you make the correct product choice for your requirement

Product specifications

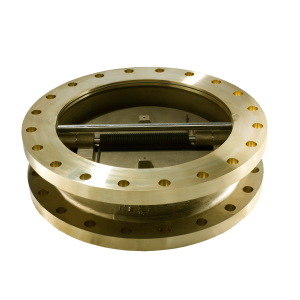

| Valve type: | Check Valves |

| Type of Industry: | Oil & Gas |

| Valve material: | Alloy |

| Aluminium | |

| Titanium | |

| Nickel | |

| Stainless Steel | |

| Duplex | |

| Bronze | |

| Pressure class: | 150 Lbs |

| Valve standards: | MSS (Manufacturers Standardization Society) |

| BSi (British Standard institute valve standards) | |

| EN (European Standard) | |

| Make / Brand: | Shipham Valves |

Company introduction

Welcome to Shipham Valves

Shipham Valves is one of the longest established and most highly respected valve manufacturers in the world.

A global reputation for excellence in product design, quality, reliability and the highest levels of customer service makes us your ideal partner for the supply of non-ferrous, composite and high alloy valves.

Since the 1930's, Shipham Valves have been active as a key valve supplier within the British Royal Navy and Ministry of Defence, satisfying the needs of a market known for its arduous requirements for product performance and reliability, quality assurance, traceability, certification and documentation.

Offshore Oil & Gas

Offshore oil and gas facilities operate in some of the world’s harshest climatic conditions leading to the requirement for non-ferrous, composite and high alloy valve solutions to overcome the challenges of the corrosive environment. Corrosion resistant materials are used extensively in the fire fighting, ballast control, cooling, water flood, sea water lift and many other critical systems.

Shipham Valves supply valve solutions in aluminium bronze and other non-ferrous corrosion resistant materials for use in many of these sea water systems. Our unique combination of valve designs, materials and size range enable us to offer the most complete package of any valve manufacturer in the world.

Our flexible approach to manufacturing enables Shipham to respond quickly to the ever changing demands of today’s offshore oil and gas project requirements.

Floating Production Systems

Floating production solutions are being used more extensively as the world seeks to extract hydrocarbons from marginal and more remote deep water locations.

These types of vessels operate in some of the world’s harshest climatic conditions leading to the requirement for non-ferrous, composite and high alloy valve solutions to overcome the challenges of the corrosive environment. Corrosion resistant materials are used extensively in the hull and topside structures in fire protection, ballast control, cooling, process and many other critical systems.

Shipham Valves provide aluminium bronze and other non-ferrous corrosion resistant valve solutions for use in many of these systems. Our unique combinations of valve designs, materials and size range enable us to offer the most comprehensive package of any valve manufacturer in the world.

Petrochemical

Processing hydrocarbons into severe service petrochemical products requires specialist equipment manufactured in high alloy materials to combat corrosion and erosion challenges.

Shipham Valves have extensive experience in both acetic acid and purified Terephthalic acid (PTA) process plants having a large installed base of valves in duplex, titanium, zirconium and hastelloy® materials.

Power Generation

With the growing demand for new energy sources around the globe and the desire to find alternative, environmentally friendly fuel sources the power generation industry is on course for a prolonged period of sustainable growth.

Shipham Valves provide a wide range of valves in aluminium bronze and duplex stainless steel materials of construction that are used extensively on sea water intake and cooling water systems on conventional gas fired and nuclear power plants. Our unique combinations of valve designs, materials and size range enable us to offer the most comprehensive package of any valve manufacturer in the world.

LNG

Shipham Valves supply aluminium bronze valve solutions which are used extensively in the sea water systems in these coastal facilities.

Applications include sea water intake, fire system ring mains and cooling water systems at the gas treatment, liquefaction and regasification terminals.

Naval Marine

Shipham Valves are a key valve supplier to the British Royal Navy, Ministry of Defence & many other Navies around the world, satisfying the needs of a market known for its arduous requirements for product performance and reliability, quality assurance, traceability, certification and documentation.

The requirement for high quality valves with different designs, sizes, operation, materials and pressure classes can be found throughout all types of modern warships including aircraft carriers, battleships, cruisers, destroyers, frigates, submarines and amphibious assault ships.

Valve and material designs for such demanding applications must meet the stringent requirements of shock, noise and vibration testing that are pre-requisite in fighting vessels while also combatting the challenges of the marine environment.