A+R-armaturen

A+R-armaturen

| Adress: |

Altenhagener Str.4 A

32107 Bad Salzuflen Germany, Germany |

| Telephone: | +49 5208 91020 |

| E-mail: | postoffice@ar-arma... |

| Website: | www.ar-armaturen.c... |

Product description

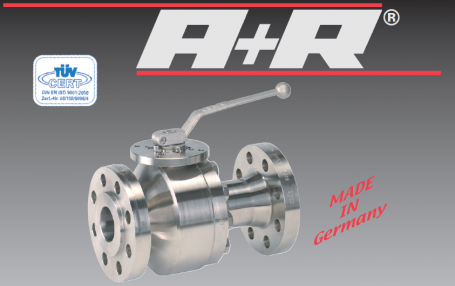

flanged-ball valves type KHF 510

DN 15, 1/2˝ up to DN 350, 14˝

ASME B 16.5 - 16.10

materials: -EGE- -SGE-

body 1.4408 1.0619

seats Metal-Graphite Metal-Graphite

ball 1.4408 1.4408

DIN EN ISO 9001:2008 - TÜV CERT -

PED 97/23/EC

manufacturing acc. to AD-2000

TA-Luft 2002

Fire-Safe Design

Application:

Steam, hot water, abrasive,

erosive Media.

Temperatur: -50 °C (-60 °F) to +350 °C (660 °F).

Product specifications

| Valve type: | Ball Valves |

| Type of Industry: | Oil & Gas |

| Pressure class: | 600 Lbs |

| Valve standards: | DN (Diametre Nominal) |

| Make / Brand: | A+R Armaturen |

Company introduction

A+R-armaturen Company

"Producing quality is our target. The quality assured standard is defined by the customer; whose needs and demands determine our direction and focus. We work together as one for a thoroughly satisfying outcome."

The highest priority for A+R Armaturen GmbH is producing ball valves which perform reliably and improve the safety & efficiency of our customers' plants. A+R delivers on its promises.

States of the art, specially designed test benches for A+R are used to ensure the highest level of quality. Only test results above and beyond the given standards will be accepted by A+R.

Metal seated A+R ball valves are produced on high precision, ultra-modern CNC machines.

Automatic or semi automatic mate lapping is used to achieve the best possible effect attaining to seat ring to ball contact. Only 100% contact of seating area on the ball surface guarantees a leakage free metal seated valve product.

Hard coating of ball and seat ring is an important part of a metal seated ball valve. Only companies having vast experience and expertise are chosen to carry out hard coating works for A+R. It is of vital importance to select the correct hard coating type for extreme applications e.g. high temperature/ pressure, high solid content, abrasion, erosion, etc. A+R can evaluate between various hard coating types to fulfill individual customer needs.

A+R History

1969 Formation of A+R Armaturen GmbH by Wolfgang Meier

1983 Began producing ball valves for various industry applications. Gerhard-Michael Decius joined the company.

1986 Retirement of Wolfgang Meier and hand over of management to Gerhard Michael Decius

1991-1993 Introduction of investment casting for high quality ball valves by A+R

Establishment of the quality insurance system ISO 9001

1995 Construction of a new A+R plant in Bad Salzuflen, Lockhausen

1996 Launch of A+R metal seated ball valves for extreme applications

2000 Installation of new machinery providing state of the art CNC technology

2002 Grand opening of the First international sales offices

2007 Gerhard-Benjamin Decius joined A+R

2008 Construction of a high bay warehouse at A+R site Bad Salzuflen, Lockhausen

Kai Köppen appointed General Manager

2010 A cutting edge 5-axis milling centre and various new CNC machines were added to the range of existing machinery

The Future

We want to ...be the first choice for ball valve manufacturing in Europe continuously improve our products for both our customers and A+R`s benefit upgrade our Research & Development, Production and Warehousing departments to move with our ever expanding business.