Penta S.r.l.

Penta S.r.l.

| Adress: |

Via Boccaccio 23

25080 Molinetto di Mazzano Brescia, Italy |

| Telephone: | +39 030 2629175 |

| E-mail: | sales1@pentavalves... |

| Website: | www.pentavalves.it |

Product description

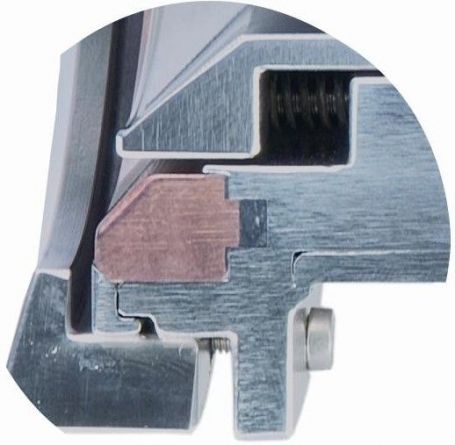

The SAT3 model is an evolution of the SAT with the inserion of two rings (called Scraper Rings) inside and outside the seats.

The Scraper Rings have to:

- clean ball surface during valve operation

- protect the seats from abrasion by fluid solid content

- avoid wedging in of solids between seat and ball surface

cause of valve blocking

- reduce dirt can fill body cavity

Like all PENTA production, valves of SAT3 series are

equipped with metallic seats in PENTAFITE that allow the

manufacturing of metal seated ball valves with Bubble tight (no leakage) suitablefor a wide range of sevices with working temperatures up to 700°C.

The typical elastic properties of PENTAFITE seats and the

fully bolted construction, allow an easy maintenance without

necessity of additional lapping of the spare seats against

the ball,

The SAT3 model is available in two version:

- Bi-directional, both with floating ball or trunnion mounted

- Uni-directional, trunnion mounted ball for applications

where pipe axis is vertical.

In this case body cavity is machined to obtain a complete

body cavity draining avoiding fluid deposit inside the valve (best for bottom tank valves).

Product specifications

| Valve type: | Slurry Valves |

| Type of Industry: | Hydrocarbon Processing |

| Water & Wastewater | |

| Mining | |

| Oil & Gas | |

| Valve material: | Carbon Steel |

| Stainless Steel | |

| Duplex | |

| Alloy | |

| Pressure class: | 300 Lbs |

| PN 40 | |

| 150 Lbs | |

| PN 16 | |

| PN 10 | |

| PN 100 | |

| 600 Lbs | |

| PN 63 | |

| Valve standards: | ASTM (American Society for Testing and Materials) |

| DIN (Deutsches Institut für Normung) | |

| EN (European Standard) | |

| BSi (British Standard institute valve standards) | |

| ASME (American Society of Mechanical Engineers) | |

| API (American Petroleum Institute) | |

| Make / Brand: | Penta S.r.l. |

Company introduction

Since 1977 Penta is involved in the design and production of

Metal seated ball valves for high temperature services

Metal seated ball valves for abrasive services (with solids)

Spring Loaded PTFE seated cryogenic ball valves

Ball valves with special designs arrangements

During its activity the Company has developed proprietary technologies for:

- Self lubricated metallic seat material PENTAFITE

- Special expanded graphite gaskets to meet very high pressures and temperatures

- Long lasting designs

More than twenty years of worldwide experience on critical services is now

available in a wide range of valve sizes and pressure classes.

All our production is 100% pressure tested to meet NO VISIBLE leakage

both in seat hydrotesting and low pressure gas seat testing.

Safety and reliability together with full satisfaction of customer’s

expectations are the main criteria on which design and manufacture

of Penta valves is based.

PENTAFITE UNIQUE TECHNOLOGY

This advanced exclusive seat material shows together:

Metallic properties, specially for which compressive

strength refers

- Low friction factors, to reduce valve torque

- Self lubricating properties, to eliminate galling

experienced with other solid metals

- High elasticity, to eliminate lapping of seat to a

specific side of the ball and to allow quick and easy

interchangeability

- High corrosion resistance