Utilities Valves

Utilities Valves

| Adress: |

Invicta House, First Avenue,

First Avenue, Trecenydd, CF83 2SD Caerphilly Merthyr Tydfil, United Kingdom |

| Telephone: | +44(0) 2920 888 779 |

| E-mail: | info@utilitiesvalv... |

| Website: | www.utilitiesvalve... |

Product description

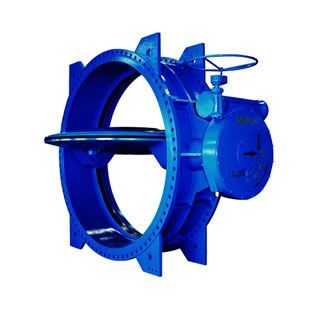

Our impressive range of Double Eccentric Butterfly valves includes Resilient and Metal Seated Valves in EN558 series 13 & 14 and BS5163, with both Aluminium Bronze and Stainless Steel Discs, in ranges DN150 to DN1200 as standard. We are fully capable of the production of DN5000 product on request. All valves are available with Hand wheel, gearbox or actuation to your specifications.

We offer fully WRAS approved EPDM and NBR materials up to DN2800 bi-directional, with other sizes to DN5000 pending.

With the Utilities Valves tradition of Innovation and development, we would like to introduce you to the UV Resilient Seated Double Eccentric butterfly valve in ranges DN150 to DN5000.

DOUBLE ECCENTRIC KEY AND INNOVATIVE FEATURES

Manufactured in GGG50 with a variety of shaft and trim materials for service conditions.

Market leading innovation and design in terms of corrosion protection and disc to shaft security.

This product features double key way and double pin, to both stub shafts for total protection against mechanical forces and anti-flutter.

Robust valve design in all respects of body, shaft and disc design, with streamlined low head loss anti flutter contour.

Strong Gearbox design to IP67 or IP68 for buried and submersible service.

High Grade materials – Seat Ring, Seal Retaining Ring and Shaft materials are selected for service conditions from 304/316 to 316L to Super Duplex.

Entire valve construction option in Bronze and Duplex/Super Duplex, placing UV as one of few to offer this technology and manufacturing capability

Unique Features

Seal Ring Locking & Corrosion Protection

Double Keyway & Pins, Shaft/Disc Connection for Added Security

Shaft Encapsulation from Flow Media & Corrosion Protection

Sealing Ring Adjustment & Corrosion Protection

Disc Lock-Block with Keyway, in any position

Product specifications

| Valve type: | Double Excentric Butterfly Valves |

| Type of Industry: | Mining |

| Oil & Gas | |

| Chemical | |

| Custom made Valves | |

| Valve material: | Stainless Steel |

| Cast Carbon steel | |

| Aluminium | |

| Pressure class: | 150 Lbs |

| Valve standards: | BSi (British Standard institute valve standards) |

| DN (Diametre Nominal) | |

| Make / Brand: | Utility Valves |

Company introduction

Utilities Valves global production capabilities enable us to balance our unique technical competence with competitive manufacturing costs offering quality engineering alongside market leading value.

Utilities Valves operate professional and effective supply line management services, providing reliable and efficient inventory and manufacturing savings for our clients.

A British-based business

Although a global company, our roots proudly lie within British engineering and manufacture. Within the UK we operate extensive facilities for Valve Assembly, Actuation, Specialist Valve manufacture and refurbishment. Utilities Valves Quality Management, R&D, Technical Sales & Customer Support teams are also headed in the UK, supplying a full range of Gate, Butterfly, Check, Air and Knife Gate valves and Hydrants. We also offer an unmatched range of “Special Applications” Valves designed to handle extreme duties, large differential pressure, high velocity flow and high energy dissipation applications.

A commitment to Innovation

Utilities Valves sit at the forefront of valve design and manufacture with our innovative new “Multi-Seal”® Low Torque resilient seated gate valve with high security shut off. Our advanced Bi-directional Double Eccentric Butterfly valves are setting new industry standards for total corrosion protection, improved flow characteristics and low “head loss” , allied with increased operating security with our unique double “disc to shaft” pin and keyway connection.

Global Technical Support

We offer technically competent engineering advice and support across all areas of our business. Our Valve Engineers are confined space trained and technically certified to inspect Valves in-situ, offering a professional assessment of the viability of refurbishment, replacement, or new installation. We can advise and assist on the commissioning and installation of Specialist Valves in all applications.